Our labs are located in the Chemistry building, on the ground floor, in rooms 10, 11, and 13J. Besides, the Western Science Center has space where radioactive materials are examined and stored. The group takes unique approaches to problems related to materials degradation, and members have access to many state-of-the-art electrochemical and surface analysis instruments.

The following electrochemical equipment is available for use by group members and can be used by non-group members on a collaborative and commercial basis. Please see the service prices and get in touch with us at [email protected] if you are interested in using the equipment.

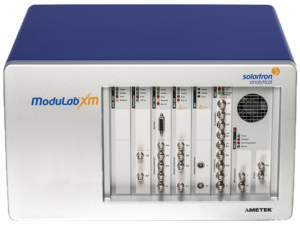

O ne of the most advanced electrochemical interfaces available. The system allows us to have up to eight high-precision independent potentiostats in one chassis or use potentiostat/frequency response analyzer (FRA) combinations to perform electrochemical impedance spectroscopy (EIS) measurements. Currently, this is the main instrument in the laboratory and delivers a full spectrum of electrochemical experiments. When used with a Faraday cage (routine in our laboratory), the system allows current measurements on the order of 100 nA or better. The group has three chassis available for use.

ne of the most advanced electrochemical interfaces available. The system allows us to have up to eight high-precision independent potentiostats in one chassis or use potentiostat/frequency response analyzer (FRA) combinations to perform electrochemical impedance spectroscopy (EIS) measurements. Currently, this is the main instrument in the laboratory and delivers a full spectrum of electrochemical experiments. When used with a Faraday cage (routine in our laboratory), the system allows current measurements on the order of 100 nA or better. The group has three chassis available for use.

This multistat is similar to the Modulab XM ECS and includes eight independent potentiostats. It is capable of making EIS measurements one channel at a time when combined with an FRA, but the measured current resolution is a little lower than that of the Modulab XM ECS system. However, these characteristics are sufficient for the vast majority of electrochemical experiments. One such system is available in the laboratory.

This multistat is similar to the Modulab XM ECS and includes eight independent potentiostats. It is capable of making EIS measurements one channel at a time when combined with an FRA, but the measured current resolution is a little lower than that of the Modulab XM ECS system. However, these characteristics are sufficient for the vast majority of electrochemical experiments. One such system is available in the laboratory.

This is a single potentiostat with characteristics close to those achievable with the Modulab XM ECS system. Being a separate system, it allows more flexibility in applications where the use of the multipotentiostats is inconvenient, like experiments with radioactive materials and those performed in anaerobic chambers. Together with a Solatron FRA, it can measure EIS with precision on par with the Modulab XM ECS system. Five such systems are available in the laboratory.

This is a single potentiostat with characteristics close to those achievable with the Modulab XM ECS system. Being a separate system, it allows more flexibility in applications where the use of the multipotentiostats is inconvenient, like experiments with radioactive materials and those performed in anaerobic chambers. Together with a Solatron FRA, it can measure EIS with precision on par with the Modulab XM ECS system. Five such systems are available in the laboratory.

These potentiostats are entry-level systems and are well-used for measurements that do not require high-precision current acquisition. While they show conventional accuracy in the current acquisition, they are excellent for work that needs a galvanostatic regime.

This is an essential instrument for use in rotating ring-disk electrode (RRDE) experiments. The unit, together with an electrode rotator (the group has three of them), allows us to investigate systems under mass transport control.

This is an essential instrument for use in rotating ring-disk electrode (RRDE) experiments. The unit, together with an electrode rotator (the group has three of them), allows us to investigate systems under mass transport control.

In addition to conventional electrochemical instrumentation, the laboratory has the following gadgets:

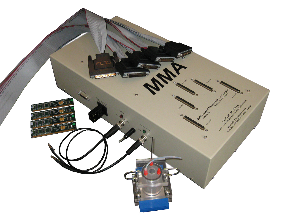

This low-power multistate allows us to perform electrochemical measurements on up to 100 electrodes at the same time. This feature enables investigations of many electrodes under the same conditions at the same time. The MMA allows a dramatic increase in work throughput and performs experiments not possible using conventional potentiostats. The system has a FRA module, which lets us perform EIS measurements on multiple electrodes.

This low-power multistate allows us to perform electrochemical measurements on up to 100 electrodes at the same time. This feature enables investigations of many electrodes under the same conditions at the same time. The MMA allows a dramatic increase in work throughput and performs experiments not possible using conventional potentiostats. The system has a FRA module, which lets us perform EIS measurements on multiple electrodes.

This resistance probe system is unique, as it was custom-made in-house. While electrochemical measurements are very effective in investigating the corrosion of metals and alloys, they require that the materials be immersed in conductive media (electrolyte solution). However, in many cases, the degradation of alloys and metals has to be investigated in poorly or non-conductive solutions (e.g., materials degradation in nuclear fuel cooling reservoirs) or gaseous media (copper corrosion in humid air under g-radiation). The PreCorMS resistance probe technique is based on the measurement of the material’s electrical resistance and has no such limitation.

This modular, state-of-the-art instrument allows users to exploit nine local electrochemistry techniques. The scanning probe electrochemistry station encompasses a range of techniques that provide complementary information. The M470 can perform scanning electrochemical microscopy (SECM), intermittent contact-SECM (ic-SECM), localized electrochemical impedance spectroscopy (LEIS), scanning vibrating electrode technique (SVET) (also known as vibrating probe), scanning Kelvin probe (SKP), scanning droplet cell (SDC) and optical surface profiling (OSP). By selecting the different modules, we can investigate the surface activity, impedance, potential, current, and topography. The combination of these allows a complete description of the sample under study to be obtained.

This modular, state-of-the-art instrument allows users to exploit nine local electrochemistry techniques. The scanning probe electrochemistry station encompasses a range of techniques that provide complementary information. The M470 can perform scanning electrochemical microscopy (SECM), intermittent contact-SECM (ic-SECM), localized electrochemical impedance spectroscopy (LEIS), scanning vibrating electrode technique (SVET) (also known as vibrating probe), scanning Kelvin probe (SKP), scanning droplet cell (SDC) and optical surface profiling (OSP). By selecting the different modules, we can investigate the surface activity, impedance, potential, current, and topography. The combination of these allows a complete description of the sample under study to be obtained.

This system consists of 1 kW xenon arc source, chopper, monochromator, fibre optics, signal detection and recovery, dark Faraday cage, and electrochemical interface with a lock-in amplifier. It allows electrochemical measurements under photoexcitation (UV-VIS). It can be used to probe the properties and defect structures of semiconducting materials, such as certain oxides and sulphides -common corrosion films on metals. It has also been used for the evaluation of photovoltaics

The hydrogen analyzer can determine the absorbed hydrogen content of metals at the sub-ppm range by mass. Typically, electrochemically treated samples are heated above their melting point to drive off any absorbed hydrogen, which is then quantified using a thermal conductivity detector in a stream of nitrogen carrier gas. Additionally, the analyzer has an IR furnace, which allows us to heat the sample from room temperature up to 900°C to release more weakly bound hydrogen. That provides the ability to distinguish between different types of adsorbed hydrogen (i.e., diffusible hydrogen or hydrogen from various traps) and calculate absorption parameters.

The hydrogen analyzer can determine the absorbed hydrogen content of metals at the sub-ppm range by mass. Typically, electrochemically treated samples are heated above their melting point to drive off any absorbed hydrogen, which is then quantified using a thermal conductivity detector in a stream of nitrogen carrier gas. Additionally, the analyzer has an IR furnace, which allows us to heat the sample from room temperature up to 900°C to release more weakly bound hydrogen. That provides the ability to distinguish between different types of adsorbed hydrogen (i.e., diffusible hydrogen or hydrogen from various traps) and calculate absorption parameters.

Another lab infrastructure allows any electrochemical experiments to be performed under well-controlled environmental conditions, such as temperature, relative humidity, and gas composition in and above the electrolyte solution. To control the gas composition, an in-house, automated gas mixing system can be employed, which allows us to control the concentration of selected gases in the mixture with which we sparge the electrolyte solution. Two high-performance anaerobic gloveboxes with oxygen concentrations of less than 0.1 ppm can be used when an extremely anaerobic atmosphere is required.

We have several modes of running temperature-controlled experiments. To control the temperature of an electrolyte solution, we can use one of several circulating thermostatic baths available in the lab. The laboratory also has a unique system that was designed and fabricated in-house for electrochemical, corrosion, and other measurements in aqueous electrolytes at temperatures above 100°C (up to ~ 250°C). The system consists of high-temperature autoclaves that have been adapted for use as electrochemical cells for elevated temperature, along with heaters, current and potential measurement devices, and a computer-controlled data acquisition system. We also have several ovens and two controlled temperature and humidity chambers, one with controlled gas composition and one with ambient air.

The lab is also outfitted with various ancillary equipment, such as polishers, Type-I water supply apparatus, balances, an inverted metallographic microscope, and a 3D printer.

Having our high-performance computer systems and collaboration with SHARCNET is critical for the group. We use the COMSOL software package for finite element modelling (FEM) to investigate the theory behind experimental data and predict the performance of materials at conditions and times not possible from a practical viewpoint.

We are also using the Arivis software package to analyze and visualize MicroCT data obtained at Surface Science Western or using synchrotron radiation at different synchrotron facilities around the globe.

All critical data on the lab computers are continually backed up and saved at an off-site location according to the highest data preservation standards.

We closely collaborate with Surface Science Western and Western Nanofab Facility. Because of such collaborations, lab members have ready access to state-of-the-art surface analytical instrumentation and the professional instrument scientists required to get the most out of the measurements. Cooperation with CNL Chalk River Laboratories also allows us to investigate materials degradation in the presence of radiation fields.