Most of us strive to leave a legacy for a few generations. A team led by Chemistry professor Jamie Noël, however, is working towards a million-year legacy – with the highest possible stakes.

Noël is principal investigator in a project analyzing how to build corrosion-proof, copper-clad canisters in which to store Canada’s radioactive nuclear energy waste.

“These containers, we want them to last forever,” said Noël, an award-winning Distinguished Research Professor. “We are considering anything and everything that could be a source of corrosion for these canisters.”

The science and process of permanently storing Canada’s nearly 3 million spent fuel bundles – plus the 90,000 more generated each year – is one of the country’s greatest environmental challenges.

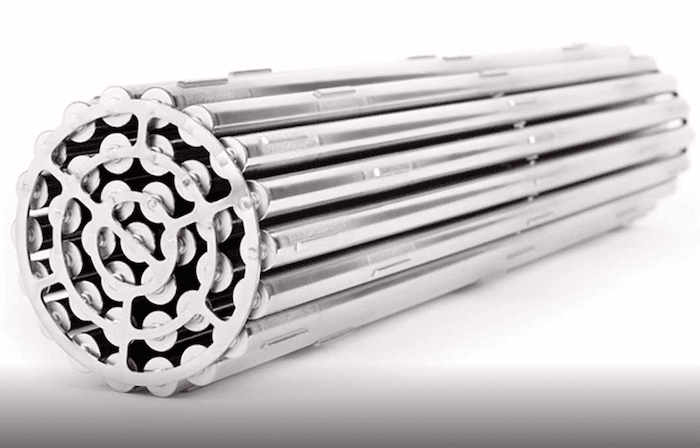

Fuel bundles are each about the size of a fireplace log, weigh 20 kilograms apiece and are made up of fuel sheaths that contain ceramic uranium pellets. Each bundle has a lifespan of about 18 months, during which it will generate enough energy to supply 100 homes for a year.

Once removed from the reactor, fuel bundles are placed in deep-water pools to cool down for 10 years. They are then placed into 70-tonne dry storage containers made of reinforced high-density concrete, about 50-cm thick and lined inside and outside with thick, rolled steel plates.

Eventually, they will need to be transferred into something permanent that won’t leak, break, shift, crack, crush or corrode over the course of a thousand millennia.

The Nuclear Waste Management Organization (NWMO) is in charge of managing long-term storage. Currently, the organization manages the storage of about 2.9 million fuel bundles (added to at a rate of about 90,000 per year).

NWMO has proposed a multiple barrier system that includes entombing the bundles in bentonite clay in an impermeable deep geologic repository. A shortlist to five willing and informed host communities have been proposed: Hornepayne, Huron-Kinloss, Ignace, Manitouwadge and South Bruce.

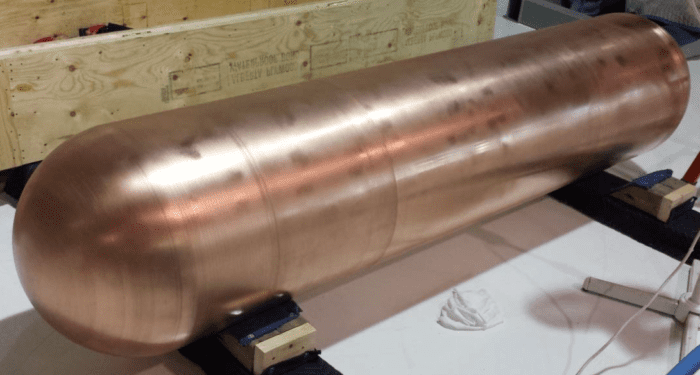

First, though, fuel bundles would be encased in heavy steel capsules clad in electroplated copper.

That’s where Noël’s team comes in.

Copper is chemically stable and non-corrosive in an oxygen-free setting. Noël is determining how thick the copper electroplate must be and how much corrosion might take place before any trace oxygen is used up or absorbed through the bentonite clay barrier.

His lab of 20 Western researchers – including Chemistry professor David Shoesmith – has grants from NWMO to study the chemical properties and processes that could make the copper cladding vulnerable to corrosion.

“You have to understand all the processes taking place at a fundamental level and be able to predict whether or not they’re going to fail in this vessel. How uniform is uniform? How smooth is smooth? All of the things we measure and predict and suggest always have to err on the side of caution.”

An extended team that includes nine academic researchers from Western, University of Toronto, York University and University of Waterloo is also into the second year of a $12-million Ontario Research Fund grant to understand the complex interactions that could lead to the degradation of engineered materials.

Their expertise includes metallurgy, electrochemistry, corrosion science, thermodynamics, hydrogeology, mineralogy, microbiology, synthetic chemistry and computer modeling.

This team and associated industry partners and international experts and agencies, totalling 65 people, met in London last month to share some of their individual and collaborative research. That includes, recently, simulating what happens to copper when encased in bentonite clay and placed at depth in the Pacific Ocean for six months.

Also in the works is an upcoming submission of an Natural Sciences and Engineering Research Council of Canada (NSERC) Collaborative Research and Training Experience (CREATE) proposal that could fund a number of students and other scientists in the four universities, as well as at other participating institutions.

“We’re looking at this project from all of the angles,” Noël said. “That’s exciting synergy, working with other people, in other fields.”

The Finnish canister, for example, is a steel shell cylinder that’s slid into a thick copper shell.

The Canadian-designed capsule is smaller, with hemispherical head-ends to eliminate the potential for tensile stress-cracks, and coated in a thinner but tighter copper shielding. It is, Noël explained, less expensive, simpler to build and – most importantly – safer.

Or at least that’s what the volumes of research are telling experts, who are drawing on international expertise and multiple layers of scientific review and critiques to test their findings.

Even so, public concerns persist about how to make any radioactive waste safe through lifetimes and eons and ice ages. For critics, Noël acknowledged, no amount of scientific rigor, engineered solutions or comprehensive answers to all the ‘what-ifs’ can allay their fears.

And as much as he understands that, he said, we still have a responsibility to find a solution to the waste already generated in storage that wasn’t designed to last hundreds of years, much less thousands.

NWMO is taking deliberate steps and is still decades away from placing the first spent fuel bundle underground.

It has spent years working with and listening to more than 18,000 Canadians, including technical specialists, the public, and Indigenous Peoples. It has narrowed the potential number of “willing and informed host communities” to five, including two in the Huron-Bruce area in Southwestern Ontario.

Nuclear power is non-carbon-emitting, consistently reliable and has a smaller land footprint than any other energy source. About half the electricity used in Canada comes from nuclear power sources (and half of that comes from the Bruce Nuclear Plant alone).

But it leaves a radioactive footprint that must also be addressed – both by disposing safely of the waste already generated and by developing new technologies that can burn more uranium and leave a smaller radioactive legacy.

“Until we get there, we have to face reality: this is what we’ve got, and how do we do this safely and properly?”